Investment Casting Manufacturer Overcome 25-Day Lead-Time Request To Win Client's Heart

Short Lead-Time. No Inventory Concern For Your Investment Casting Need

Precise Casting Process With a Strong Engineering Team

Precise Casting Process With a Strong Engineering Team

"You can't predict who's your next big client, you can only grasp every opportunity to prevent missing one." said the president of Lin Chiao. One evening, Lin Chiao, a Taiwanese investment casting manufacturer, received a call from Magnate Technology Co., Ltd. who requested bottle clamp fabrication using lost wax casting technology.

The manager asked a few questions on the phone: "What's your company's product development ability? What's your production lead-time? What's your monthly production capacity?" and also claimed that they had been cooperating with another metal casting company for a long time, but their low volume production wasn't favorable and their worsening casting performance made the customer search for other solutions, but there was only 25 days left before delivery. Normally it takes about two months to finish the whole casting process and Lin Chiao was asked for a 25-day lead-time. After a short discussion, Lin Chiao took the job.

Magnate Technology Co., Ltd. is a Taiwan-based company that has been supplying and cooperating with world-leading companies including Mitsubishi, HONDA Jet, etc. Their business has expanded to dynamic industries containing aerospace industry, food machine components, semi-conductor & electronic components and other precision components.

For 24 years, Lin Chiao has been accumulating lost wax casting skills in order to deliver professional investment casting; they knew they could make it happen in a short time. Subsequently, Lin Chiao was able to achieve the customer's short lead-time requirement and fabricated bottle clamps without pinholes. It is the 8th year since Lin Chiao accomplished the target, and their cooperation continues since then.

From understanding the design, discussing the manufacturing possibility, mold designing and making, product prototyping to massive production and testing; achieving all the jobs in 25-days is crucial, and manufacturing 100% perfect products with high tolerance is just as important. Therefore, every investment casting process requires precision, and the machine has to be in the great condition. After the goal was set, mold design and making was done in 7 days, prototyping was done in 3 days, tolling was done in 2 days, plus SGS testing and packaging, etc.

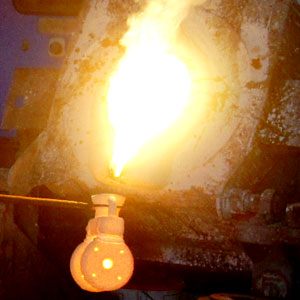

There are many casting process factors which affect wax casting tolerances, including wax temperature, firing temperature, die temperature, pressure of injection, shell composition strength, rate of cooling, etc.

Particularly in shell composition, when the shell is placed into an oven where it is fired for a period of time, the solidness of the shell affects the next process, which is when molten metal is poured into the shell. Great shell strength causes high quality product stability. Since the shell's soundness is decisive, if the shell can't handle the melton metal and the shell breaks or inflates, so humidity control has become critically important for steel investment casting.

At Lin Chiao, investment casting process environment control is enhanced by applying a vacuum or minimizing the humidity to conduct a perfect shell condition.

Nowadays, buyers require short lead-time and sell without inventory. To fabricate machine equipment using investment casting technology in 25 days and get results with high quality production, process management standardization becomes critically important. After knowing the fabrication possibility of bottle clamp, each process' execution period is set and performed exactly.

![]() About Lin Chiao – a high quality investment casting manufacturer

About Lin Chiao – a high quality investment casting manufacturer

Penetration inspection line, Layout machine, Tensile testing Machine, and Chemical analyzer

(images from left to right)

Article sections