- 1. Grundfos' Selection Of Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

- 2. Investment Casting For The Largest Orthotics Prosthetic Parts Supplier In The U.S.

- 3. Investment Casting Manufacturer Overcome 25-Day Lead-Time Request To Win Client's Heart

- 4. No More Sand Casting For Big Object, Investment Casting Is The Future

- 5. Investment casting process Is Done With Excellent Design By Lin Chiao

- 6. UKAS, ISO, SGS Certified Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

- 7. Lin Chiao Investment Casting Video and Picture

- 8. Lin Chiao's Investment Casting in 2016

- 9. Contact A Lost Wax Casting Supplier Now!

- 10. Lin Chiao Casting Co., Ltd. Privacy Policy

1.Grundfos' Selection Of Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

Grundfos' Selection of Investment Casting Manufacturer – Lin Chiao

In 2014, the cooperation between Lin Chiao and Grundfos is going one step further; Lin Chiao is no longer just an investment casting OEM manufacturer. Instead of just fabricating pumps based on Grundfos' design, after years of working together, Grundfos now would first provide a sketch followed by a lengthy discussion about the technical aspects based on the design. Finally, Lin Chiao delivers a final design according to the discussion. It is a statement about how Grundfos respects Lin Chiao's professionalism, and Lin Chiao's performance has been fantastic.

The world-class investment casting manufacturer Lin Chiao has received 30-ton pump orders from Grundfos Taiwan, one of the world’s leading pump manufacturers in Dammar.

Opportunity is for people who are ready. When Grundfos was looking for an investment casting manufacturer, Lin Chiao was all ready for the job.

The first procurement was made 7-years later after Lin Chiao delivered 9 sample pumps at the beginning. Seven years of communication and evaluation seems long, but the result was delightful. Grundfos' recent 30 tons pump order was an acknowledgement of Lin Chiao's investment casting skill.

Seven years ago, Grundfos was cooperating with a fairly big metal casting company using sand casting to make pumps, however, lost wax casting's advantage attracted them to switch to lost wax casting. Pinholes occurred during lost wax casting process; hence, Grundfos had to look for other suppliers for solutions.

When the manager of Grundfos showed up at the door with a large pump after a long drive all around Taiwan searching for an investment casting manufacturer, he asked Lin Chiao whether they can do it or not. He mentioned about the pinhole dilemmas with the other manufacturer, and would like to hear about the solutions.

Lin Chiao explained and proposed the pinhole solutions and Grundfos had Lin Chiao to make the samples. As a result, Lin Chiao had surpassed their large competitors and won the competition because of the high quality stainless steel pumps they made.

Based on the pump from the manager of Grundfos, a large wax injection machine that would allow 500mm*500mm mold size was required. Lin Chiao fabricated 9 pumps for Grundfos, and the pumps were tested for two years. While Lin Chiao was wondering about the test results, two years later, Grundfos asked for a quotation. After submitting the quotation, Lin Chiao waited for another two years and finally heard back from them. Grundfos made the first order from Lin Chiao; it was the first time after four years of waiting and Grundfos took it very seriously.

From mold making, sample testing, small amount production, different sizes of pump fabrication until the recent 30-ton pump ordering, it was a seven-year period of assurance.

For seven years, Lin Chiao has been performing high standard investment casting technology and providing professional consulting based on 24 years of seasoned experience.

Highly Precise. Appealing. Intricate Shapes Metal Casting – Investment Casting

Investment casting delivers lots of advantages for metal casting, including high production capability, especially for small or highly complex components, extremely good surface finish with very little machining, highly accurate and reliable form of casting, any components comprised of metals that are hard to machine or fabricate are great candidates for investment casting.

The Grundfos Group is represented by more than 80 companies in more than 55 countries. Today they are the world's largest manufacturer of circulators, covering approximately 50% of the world market for these pumps. Grundfos produces controlling pumps including axial flow propeller pump, submersible pumps, speed-controlled pumps, booster module piston pumps, Multistage centrifugal pumps and multi-stage submersible pumps to provide industrial solutions and Lin Chiao plays an important role providing high quality pumps with up-to-date investment casting technology.

![]() About Lin Chiao – a World-Class Investment Casting Manufacturer

About Lin Chiao – a World-Class Investment Casting Manufacturer

Trimec Industries

1/16 Atkinson Road,

Taren Point NSW 2229.

Sydney, Australia

To: Lin Chiao Casting Co., Ltd.

No.19-1, Hsing Kung Rd.,

Yung Kang, Tainan, Taiwan 710.

R.O.C.

Hi Pax,

Good the hear from you, Hope you are well.

Trimec Industries is very pleased with our relationship with your Company. Your quick responses along with your company's commitment to supplying quality products and professional advice is outstanding.

Having personally visited your manufacturing facilities we would recommend other companies seeking investment casting products to consider using Lin Chiao Casting Co., Ltd. as a supplier.

Regards

Keith Daly

General Manager

Trimec Industries

2.Investment Casting For The Largest Orthotics Prosthetic Parts Supplier In The U.S.

Lin Chiao's Investment Casting For The Largest Orthotics Prosthetic Parts Supplier In The U.S.

In the U.S., there are five big orthopaedic device companies, and Orthomerica Products, Inc. is the largest compared to others. Orthomerica Products delivers the most functional and comfortable orthotics prosthetic parts for muscle weakness and paralysis of body parts.

Orthomerica Products visited a few OEM lost wax casting suppliers in Taiwan and asked for completed SGS reports, but not every supplier passed the tests.

For prosthetic and orthotics components, investment casting metal-forming technology is applied to ensure each device's safety. Because of orthotics prosthetic parts' complex shape, one-piece casting is required. Therefore, a skillful lost wax investment casting manufacturer is critical importance.

After a series of rigorous assessments, Orthomerica Products chose a Taiwanese investment casting manufacturer, Lin Chiao Casting Co., Ltd., above other competitors. At the beginning, Orthomerica Products' was procuring half of the orthotics prosthetic parts from Lin Chiao, years later, due to their excellent performance, it is now 100% supplied by Lin Chiao.

Prosthetic and orthotics components metal casting

Since investment casting was discovered, the industry has grown steadily because of the low tooling cost, time saving, better finishing and the optional alloy choices. Investment casting allows you to choose various sizes of orthotics and prosthetics, from stainless steel hip orthoses to foot and ankle orthoses, and it also delivers great safety for the users.

Particular for orthopaedic device, while the world economy continues to face its difficulties, the healthcare sector in general and the orthotics prosthetic parts industry in particular is growing strong. For the level of detail and precision necessary for metal orthotics prosthetic parts, Lin Chiao uses the lost wax casting technique to meet tough requirements.

SGS tested prosthetics, orthotics

Orthomerica Products have chosen Lin Chiao, a Taiwanese lost wax casting supplier, as a quality manufacturer of their orthotics prosthetic parts. The leg orthosis attached to a patient's leg must be supportive, functional and comfortable, and any possible injuries caused by a defeated product are unacceptable.

For Orthomerica Products, each orthosis (KAFO/AFO) should be manufactured to the highest standard and met the criteria. Therefore, when choosing an investment casting component manufacturer, requirements are extremely strict. Based on 24-years of lost wax casting experience, Lin Chiao's stainless steel component passed all of the physical tests at SGS, and fatigue tests in the U.S. by Orthomerica Products.

Special formula prosthetic orthotics components' requests

Material formula is an important factor for lost wax casting ; it affects stainless steel component's strength, torque and fatigue capabilities. To achieve Orthomerica Products' high expectation on prosthetic and orthotics components, control of slurries, material formula adjustment and experiment were performed consistently.

Orthotics prosthetic parts with SGS reports and ROHS approval

Tensile testing machine

For orthosis component's physical tests, they include hardness tests, tensile strength tests, roughness tests, torque tests, fatigue tests, fracture tests and life cycle tests.

Water soluble wax for wax removal

Lin Chiao started to apply water soluble wax to enhance complex shape equipment's accuracy. For intricate and detailed stainless steel orthosis parts, water soluble wax is applied for fast wax removal of axle centers or inner wholes.

![]() About Lin Chiao – a high quality investment casting manufacturer

About Lin Chiao – a high quality investment casting manufacturer

3.Investment Casting Manufacturer Overcome 25-Day Lead-Time Request To Win Client's Heart

Investment Casting Manufacturer, Lin Chiao, Overcome 25-Day Lead-Time Request To Win Client's Heart

"You can't predict who's your next big client, you can only grasp every opportunity to prevent missing one." said the president of Lin Chiao. One evening, Lin Chiao, a Taiwanese investment casting manufacturer, received a call from Magnate Technology Co., Ltd. who requested bottle clamp fabrication using lost wax casting technology.

The manager asked a few questions on the phone: "What's your company's product development ability? What's your production lead-time? What's your monthly production capacity?" and also claimed that they had been cooperating with another metal casting company for a long time, but their low volume production wasn't favorable and their worsening casting performance made the customer search for other solutions, but there was only 25 days left before delivery. Normally it takes about two months to finish the whole casting process and Lin Chiao was asked for a 25-day lead-time. After a short discussion, Lin Chiao took the job.

About Magnate Technology Co., Ltd.

Magnate Technology Co., Ltd. is a Taiwan-based company that has been supplying and cooperating with world-leading companies including Mitsubishi, HONDA Jet, etc. Their business has expanded to dynamic industries containing aerospace industry, food machine components, semi-conductor & electronic components and other precision components.

About Lin Chiao Casting Co., Ltd.

For 24 years, Lin Chiao has been accumulating lost wax casting skills in order to deliver professional investment casting; they knew they could make it happen in a short time. Subsequently, Lin Chiao was able to achieve the customer's short lead-time requirement and fabricated bottle clamps without pinholes. It is the 8th year since Lin Chiao accomplished the target, and their cooperation continues since then.

7 days mold making. 3 days rapid prototyping. 2 days tooling. – fast and high quality investment casting

From understanding the design, discussing the manufacturing possibility, mold designing and making, product prototyping to massive production and testing; achieving all the jobs in 25-days is crucial, and manufacturing 100% perfect products with high tolerance is just as important. Therefore, every investment casting process requires precision, and the machine has to be in the great condition. After the goal was set, mold design and making was done in 7 days, prototyping was done in 3 days, tolling was done in 2 days, plus SGS testing and packaging, etc.

Factors for making perfect lost wax casting product

There are many casting process factors which affect wax casting tolerances, including wax temperature, firing temperature, die temperature, pressure of injection, shell composition strength, rate of cooling, etc.

Particularly in shell composition, when the shell is placed into an oven where it is fired for a period of time, the solidness of the shell affects the next process, which is when molten metal is poured into the shell. Great shell strength causes high quality product stability. Since the shell's soundness is decisive, if the shell can't handle the melton metal and the shell breaks or inflates, so humidity control has become critically important for steel investment casting.

At Lin Chiao, investment casting process environment control is enhanced by applying a vacuum or minimizing the humidity to conduct a perfect shell condition.

Short Lead-Time. Sell Without Inventory Casting Process

Nowadays, buyers require short lead-time and sell without inventory. To fabricate machine equipment using investment casting technology in 25 days and get results with high quality production, process management standardization becomes critically important. After knowing the fabrication possibility of bottle clamp, each process' execution period is set and performed exactly.

![]() About Lin Chiao – a high quality investment casting manufacturer

About Lin Chiao – a high quality investment casting manufacturer

Penetration inspection line, Layout machine, Tensile testing Machine, and Chemical analyzer

(images from left to right)

4.No More Sand Casting For Big Object, Investment Casting Is The Future

No More Sand Casting For Big Object, Investment Casting Is The Future

HYDAC is a worldwide supplier of fluid power solutions and their products cover a wide range of mobile and stationary mechanized equipment. Because of the large size of pumps and valves for fluid power components, they were originally using sand castings to fabricate the equipment; however, the advantages of investment casting prompted them to change. Lin Chiao is a Taiwanese lost wax casting manufacturer and was selected by HYDAC for the transition.

Since the casting process was specifically designed for sand casting, Lin Chiao had to modify the process to meet lost wax casting's process criteria.

"It wasn't all that smooth switching the process from sand casting to investment casting; the design of sand casting might be too thick or too thin when applying to lost wax casting's process, so the adjustment was essential. Our casting engineering team had to upgrade their technologies in order to manufacture the equipment, it was a learning experience." said by the manager of Lin Chiao. As a consequence, Lin Chiao's casting equipment was tested as level II after conducting x-ray fluorescent chemistry test, which met HYDAC's high quality policy.

- Advantage of lost wax casting:

- For investment casting size and weight capacity, 700mm (100kg) is the maximum and 200mm (10kg) is the minimum.

- The tolerance and limitations of Investment Casting dimensions, there are several factors including size, angles, flatness and weight. Therefore, when you consult with Lin Chiao, a professional assessment and report will be provided based on your casting product.

- No restraint on investment materials, casting material can be stainless steel, carbon steel, carbon tool steel and high temperature steel, etc. Lin Chiao has casted over 40 steel materials in 24 years, including the recent popular one, Hastelloy C-22.

- Suitable for complex shape model, precise and no tooling required.

- Favorable for massive production and no waste of material.

| Sand | Permanent Mold | Investment | Comp | Die | |

|---|---|---|---|---|---|

| Strength | Good | Best | Good | Best | Good |

| Structural Density | Good | Best | Good | Best | Fair |

| Reproducibility | Fair | Good | Good | Best | Best |

| Pressure Tightness | Good | Best | Good | Best | Fair |

| Cost per Piece | Fair | Good | Poor | Poor | Best |

| Production Rate | Fair | Good | Poor | Fair | Best |

| Alloy Range | Best | Good | Good | Good | Fair |

| Tolerances | Fair | Good | Best | Best | Best |

| Design Flexibility | Best | Good | Best | Best | Fair |

| Size Limitation | Best | Good | Fair | Good | Good |

| Surface Finish | Fair | Good | Best | Best | Best |

| Tooling Lead Time | Best | Good | Good | Fair | Good |

| Mold Cost | Best | Good | Good | Poor | Fair |

5.Investment casting process Is Done With Excellent Design By Lin Chiao

Investment casting process Is Done With Excellent Design By Lin Chiao

There were two important issues that influence cost in lost wax casting project, the production time and the cost in production. To save production time, you will need a quality casting manufacturer to provide correct judgments based on the sustained casting experience and Lin Chiao's 24-year of metal casting experience can assist you to achieve your goals.

Rigorous and Innovative Casting Process - Step 1: Wax Pattern Making

Investment Casting Engineering Team - Cast-Friendly Design

When Lin Chiao's engineering team receives a product design from a buyer, Lin Chiao's engineering team would gather together to discuss the melting point and to find out the possible difficulties during casting, and managers from each department will have a meeting to discuss the casting process from their perspective.

Lin Chiao's 24-years of alloy casting experience allow them to come up with innovative solutions to provide an accurate and versatile investment casting process.

High Quality Investment Casting Mould Making

Lin Chiao has accumulated more than 20,000 molds after being a wax investment casting manufacturer for 24 years. Building a metal casting mold is different compared to others; you need a place where the alloy is poured into and mold maker needs to understand the concept of how to build a mold when the shape complicated.

Rapid Prototyping

Lin Chiao offers rapid prototyping for investment casting in a variety of alloys including stainless steel, carbon steel, nickel steel, iron casting, etc. When you receive Lin Chiao's rapid prototyping, the product is fully developed. Lin Chiao provides flexibility in production quantities, whether for a quick rapid prototype solution, small production or a high quantity ordering.

Wax Pattern / Wax Injection Condition, Time and Stability

When injecting wax into the mold, the wax pouring pressure (7~12kg/cm² or 50 kg/cm²), pre-heat mold temperature, wax injection time and temperature, wax pattern injection room temperature and the mold cooling method after wax is injected are the important factors for the wax injection process. Therefore, there are decisions that need to be made, and unprofessional judgment can lead to poor results. At Lin Chiao, water soluble wax, which can be dissolved in room temperature, is applied to the parts or angles that are hard to remove from the wax.

Wax Pattern Assembly

Once cooled, the wax pattern is removed from the mold, staff would remove the burrs on the wax pattern and make sure the surface is clear. When are they done, they are ready for casting tree fabrication.

pump wax pattern casting process

Casting Tree and Sprue

Every wax pattern can be processed individually depending on component size. They are attached to a wax runner and joined with a pouring cone, which is called casting tree or pattern cluster. Every wax pattern can be processed individually depending on component size. The wax patterns are attached to a wax gating poll with a runner, and the whole thing is referred to as a tree, pattern cluster or sprue.

Rigorous and Innovative Casting Process – Step 2: Ceramic Slurry and Stucco

Shell Making of investment casting process – Dipping

Shell making is a paramount step; if you fail to make the shell, the whole lost wax casting process is ruined, therefore, the strength of the shell has to be strong enough to handle the following process. Ceramic shell is a combination of ceramic slurry, which contains colloidal silica, alumina, stucco, etc. The tree is dipped in the ceramic slurry for the suitable thickness; it is the first preparation for molten metal pouring processing. The casting tree is dipped in silica gel for better attachment on ceramic slurry dipping.

Sand Coating (Stucco)

After the ceramic slurry dipping, the whole tree is coated with sand which is called stucco. The ceramic stucco procedure is decided during the engineering meeting. There are six times of ceramic dipping and ceramic stucco, and the stucco process started with the thinnest sand to the roughest sand. It takes about three days to finish the whole process between the drying time and procedures. The drying process is performed in an adequate time to avoid cracks. There are various sand coating methods and it depends on the density requirement.

Rigorous and Innovative Casting Process – Step 3: Shell Mold Firing

Casting mold firing time and temperature are decided during the meeting based on years of investment casting experience. Investment casting molds are fired in an oven at 1800 degrees Fahrenheit using steam to remove any volatiles. The molds are removed from the oven and placed on a support device and are ready for molten metal pouring. Melted wax is recycled for the next usage.

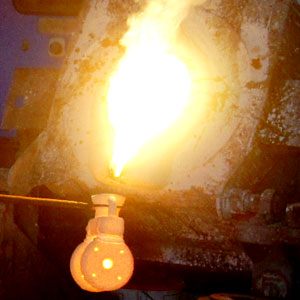

Molten Metal Pouring

The liquid metal is poured in an investment casting shell; time and temperature are important factors for this step.

Rigorous and Innovative Casting Process – Step 4: Casting Shell Knockout

Shell Knockout Using Shaking Machine

Knock off the ceramic shell by

shaking machine

After the molten metal is poured into the shell, a vibrating machine would shake the ceramic shell out of the flask. The shaking time depends on the casting component, it can be 5 or 7 seconds.

Heat Treatment

To even every steel material’s quality, sometimes heat treatment is conducted.

Acid Washing For Steel

Acid washing is a casting process to enforce the surface of steel to avoid rust.

Steel Bead Cleaning Machine For Casting Component

Bead cleaning machine is operated under high pressure which allows beads to clean up remaining ceramic shell in a high pressure environment.

Burr Free Treatment, Polishing Casting Process

Surface treatment is done to create a great tolerance and surface finishing.

- The Equipments in Lin Chiao for investment casting process:

- Wax Reclamation Vat & Static Containing Vat

- Turntable Type Wax Pattern Injection Machine

- High Pressure Single-head Wax Injection Machine

- Wax Sprue Injection Machine

- Standard Wax Injection Machine

- Soluble Wax Injection Machine

- Wax Pattern Automatic Conveying System From Wax Pattern Modification Process, Wax Pattern Cleaning to Dipping Process

- Fluid Dipping Vat

- Sand Fluidizer Bed Collector Vat

- Automatic Conveying System for Dipping Process

- Steam De-waxing Machine

- Fully-Automatic High-Speed Wax Reclamation and Conveying System

- Sintering Furnace

- High Frequency Melting Furnace

- Shell Mold Remover

- Cutting Machine

- Polishing and Grinding Machine

- Automatic Pickling Processing Setup

- Welding Machine

- Roller Type Sand Blasting Machine

- Platform Type Sand Blasting Machine

- Close Type Small Sand Blasting Machine

- Chemical Analyzer

- Hydraulic Pressure Machine

- Lab Testing Equipment For Investment Casting Products:

- Metal Spectrometer

- 2.5D Manual Measuring Machine

- Granite Base

- Tensile testing Machine

- Micro Hardness Testing Machine

- Grinding and Polishing Machine

- Mounting Press Machine

- Chemical Analyzer

- Hydraulic Pressure Machine

Casting Process

6.UKAS, ISO, SGS Certified Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

UKAS, ISO, SGS Certified Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

Lin Chiao's up-to-date facility and equipment blend well with their 24 years of investment casting experience.

For 24 years, Lin Chiao has always adopted new steel materials and new methods such as Hastelloy C-22, water soluble wax to enhance each casting product's accuracy. Lin Chiao not only is a lost wax casting manufacturer, they are also a consultant who's capable of providing professional advice based on their seasonal experience.

Lin Chiao's lost wax investment casting is applied to various equipment including orthopaedic devices, industrial pumps, bottle clamps, mobile and stationary mechanized equipment, large sized pumps and valves, etc.

Investment castingmakes use of most steel alloys containing stainless steel, carbon steel, carbon tool steel and high temperature steel, and Lin Chiao has processed more than 40 steel materials.

Their recent usage of hastelloy C-22 is an alloy which is resistant to abrasion, high temperature, thermal shock and oxidation. Lin Chiao provides great flexibility for rapid prototyping, small or big quantity orders.

Lin Chiao is an investment casting manufacturer with 24 years of metal casting experience

Investment casting is a job that needs seasoned casting experience in order to accomplish casting metal products that have great performance. Lin Chiao has been supplying casting process with innovative solutions to the international buyers including Grundfos, Orthomerica Products, Inc., Magnate Technology Co., Ltd., HYDAC, etc. Their casting products containing pumps, orthopaedic device, bottle clamps wide range of mobile and stationary mechanized equipment, etc. Lin Chiao is a lost wax casting service provider with UKAS, ISO, SGS Certifications, which prove their world-class casting process for the international clients.

7.Lin Chiao Investment Casting Video and Picture

Lin Chiao - World Class Level Of Investment Casting Technology

Lin Chiao's Investment Casting (Lost Wax Casting) Products - all alloys valve, pump, pipe fitting, machine parts, general parts, automobile parts, manifold, marine parts, hardware, impeller and turbine, human body orthosis, etc.

Providing precision castings in all alloys, Lin Chiao's casting method is certified and capable of designing complex shapes of casting, which is why Lin Quiao serves worldwide clients with profession industrial solutions.

Lin Chiao's investment casting products

Lin Chiao's investment casting including wide range of industries, such as semiconductor equipment, marine part, controlling pump, orthopaedic device, medical.

The state-of-the-art investment casting engineering, production facility and test lab is why Lin Chiao is still being able to provide top quality products for their customers.

Lin Chiao's Precision Investment Casting (Lost Wax Casting) Technology

Lin Chiao's investment casting (Lost Wax Casting) technology is tailored to meet your specific standards.

-

Valve

-

Pump

-

Pipe Fitting

-

Machine Parts

-

General Parts

-

Automobile Parts

-

Manifold

-

Marine Parts

-

Hardware

-

Impeller & Turbine

-

Human Body Orthosis

Lin Chiao never stops developing their casting skill on special metal alloys; so far there are AISI 303, Hastelloy C-22, ASTM A494 and CW-12MW. And casting product includes valves, pumps, pipe fittings, machine parts, general parts, automobile parts, manifold, marine parts, hardwares, impeller and turbines, human body orthoses, which are manufactured to perform the best.

Lin Chiao's Precision Investment Casting (Lost Wax Casting) Processing

From mold design, mold management, wax injection, wax pattern, deburring, tree assembling, slurry dipping, ceramic stuccoing, drying, dewaxing, shell sintering, melting and pouring, shell and tree removal, sprue removal, bead blasting, pickling and drying, all investment casting processes are conducted rigorously.

Investment casting processing

Step 1: Mode Design

Step 2: Mode Management

Step 3: Wax Injection

Step 4: Getting Wax Pattern

Step 5: Deburing Wax Pattern

Step 6: Tree Assembling

Step 7: Dipping in the Slurry

Step 8: Ceramic Stuccoing

Step 9: Drying

Step 10: Dewax

Step 11: Shell Sintering

Step 12: Melting & Pouring

Step 13: Shell Removal

Step 14: Tree Removal

Step 15: Sprue Removal

Step 16: Bead Blasting

Step 17: Pickling

Step 18: Visual inspection

Step 19: OQC

Step 20: Delivery

Lin Chiao's Precision Investment Casting (Lost Wax Casting) Quality Control

-

Automobile parts

-

Pipe fitting

Tensile test, hardness test, 2.5D measuring inspection and metal spectrometer, all of the test equipment is used to ensure 100% quality control.

Lin Chiao Company Introduction - The Investment Casting Expert

8.Lin Chiao's Investment Casting in 2016

Lin Chiao Upgrades to Meet World Class Level of Investment Casting

For Lin Chiao, 2016 is a year for better work environment, production efficiency and greener globe.

Lin Chiao had a prosperous year in 2015. To stay competitive in the investment casting industry, In 2016, they've been upgrading equipment in order to achieve a higher level. Lin Chiao knows that clients care about the manufacturing plant's design, in addition to its safety for staff, processing management and possesses of equipment.

Therefore, Lin Chiao’s improvements include a wax injection machine, dewax furnace, sintering furnace, auto wax dispenser and metal spectrometer replacement. All of the upgrading is to achieve an increase in investment casting production capability, high quality casting results and cost-savings.

Because of the procurement of new equipment, Lin Chiao has been adjusting production lines and changing the look of the plant to create a better work environment. In Lin Chiao, ERP system is applied to enforce the stabilization of the investment casting process.

With metal alloys that contain dynamic elements, the investment casting process becomes more complicated. Lin Chiao never stops developing their casting skill on special metal alloys; so far there are AISI 303, Hastelloy C-22, ASTM A494 and CW-12MW. Various alloys are available in Lin Chiao to meet international clients' specific requirements.

Wax Injection Machine

Due to the increased requests for larger objects' investment casting, Lin Chiao has purchased a wax injection machine that will allow them to fabricate valves and pumps up to a maximum size of 600mm*600mm*600mm. To make it easier for operators, mold handling equipment is supplied.

Dewax Furnace and Sintering Furnace

For old dewax furnace and sintering furnace, they burn 0.5% low sulfur fuel oil to increase the temperature. To decrease carbon pollution and energy-saving, Lin Chiao uses electronic dewax furnace and sintering furnace to be environmentally friendly.

Auto Wax Dispenser

For the old wax dispenser, wax refilling is done by staff. With the new auto wax dispenser, it is automatically refilled. The auto wax refilling system not only can increase production efficiency but also prevents injury.

Metal Spectrometer

To achieve each client's high standards and ensure the quality of raw material, Lin Chiao has acquired a metal spectrometer. The new metal spectrometer's multi-model testing can detect each individual metal's element or the percentage of various properties in an alloy - quickly, accurately and efficiently. By using metal spectrometer, raw material quality is controlled and casted pump and valve's quality is ensured.

9.Contact A Lost Wax Casting Supplier Now!

lost wax casting Service Provider With 24-Year of Experience

Lin Chiao's up-to-date facility and equipment blend well with their 24 years of investment casting experience. For 24 years, Lin Chiao has always adopted new steel materials and new methods such as Hastelloy C-22, water soluble wax to enhance each casting product's accuracy. Lin Chiao not only is a lost wax casting manufacturer, they are also a consultant who's capable of providing professional advice based on their seasonal experience.

10.Lin Chiao Casting Co., Ltd. Privacy Policy

Ready-Online.com websites (collectively “Ready-Online.com“) refer to sites hosted on the Ready-Online.com domains and subdomains thereof. Ready-Online.com website provides a platform for Lin Chiao Casting Co., Ltd. to showcase their stories and products in order to attract visitors with product inquiries. When visitors send inquiries, information obtained in connection with the site may be used by Lin Chiao Casting Co., Ltd. Ready-Online.com regularly collects and processes information about visitors who use the website and inquiry form which we operate and control, and for which we may be deemed to act as the Data Controller.

Personal Information You Provide to Us through Our Site.

Certain visitors choose to interact with Ready-Online.com in ways that require Ready-Online.com to gather personally-identifying information. The amount and type of information that Ready-Online.com gathers depends on the nature of the interaction. We collect, process and use your personal data for specific purposes if you have given your consent to the collection, processing and use of specific personal data for such purposes. You may withdraw your consent any time.

The types of personal information may include:

Company name, contact name, job title, company website, country, business type, email, telephone number, fax number, address.

Cookie:

There is a technology called "cookies" which is an element of data that a website can send to your browser which may then store on your system. Some Site pages use cookies so that we can better serve you when you return to our Site. You can set your browser to notify you when you receive a cookie, giving the chance to decide whether to accept it.

We use Tract ID (cookies) to collect and store information when you visit our website; the information is saved at Amazon Web Services (AWS) and used to identify your browser or device.

Cookies do not harm your computer and do not contain any viruses. Cookies help make our website more user-friendly, efficient, and secure. Cookies are small text files that are stored on your computer and saved by your browser. Using cookies enables us to provide you with certain features and provides us with information regarding website visits.

Web analysis with Google Analytics

We use Google Analytics to analyze user activity in order to improve the Website. For example, using Cookies we can look at aggregate patterns like the average number of searches that users perform, what keywords users searched, countries and languages. We can use such analysis to gain insights about how to improve the functionality and experience of the website. You can visit Google Analytics’ Privacy Policy Privacy Policy at: https://policies.google.com/technologies/cookies.

Your Information Collected from Other Technologies

Besides Cookie, we use other technologies to improve your user experience and the overall quality of our services by collecting the information below:

[site visitor] visited website (URL)

[site visitor] IP Address

[site visitor] Internet Connection Device Brand, Model and OS

[site visitor] Internet Connection Device Browser, Resolution, Color

[site visitor] GeoIP

[site visitor] ISP

How We Use Your Personal Information

Our client will supply information on products or any other professional information based on inquiries received. Without your explicit consent or a legal basis, your personal data or browse history is not passed on to third parties outside the scope. Part of the data is collected to ensure the proper functioning of the website. Other data can be used to analyze how visitors use the site.

Information, Blocking, Deletion

As permitted by law, you have the right to be provided at any time with information free of charge about any of your personal data that is stored as well as its origin, the recipient and the purpose for which it has been processed. You also have the right to have this data corrected, blocked or deleted. You can contact us (rita@ready-market.com) at any time using the address given in our legal notice if you have further questions on the topic of personal data.

All the collected information is saved for 24 months on Amazon Web Services (AWS) and regularly deleted every month.

The Protection of Your Personal Data

Your personal data is stored on Amazon Web Services (AWS). AWS Announces CISPE Membership and Compliance with First-Ever Code of Conduct for Data Protection in the Cloud.

Information Security

We use standard security technology SSL or HTTPS standard technology for keeping an internet connection secure and safeguarding any sensitive data that is being sent between two systems, preventing criminals from reading and modifying any information transferred, including potential personal details.

Changes to This Privacy Policy

We may update this Privacy Policy to reflect changes to our information practices. If we make any material changes we will notify you by email (sent to the e-mail address specified in your account) or by means of a notice on this website prior to the change becoming effective.

Contact Us

If you have any questions about the website, cookie, Google Analytics, please contact:rita@ready-market.com

If you have any questions about inquiry content or personal information, please contact:

Address: No. 19-1, Xinggong Road, Yongkang District, 710

Phone: 06 233 0700

Article sections

- Grundfos' Selection Of Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

- Investment Casting For The Largest Orthotics Prosthetic Parts Supplier In The U.S.

- Investment Casting Manufacturer Overcome 25-Day Lead-Time Request To Win Client's Heart

- No More Sand Casting For Big Object, Investment Casting Is The Future

- Investment casting process Is Done With Excellent Design By Lin Chiao

- UKAS, ISO, SGS Certified Investment Casting Manufacturer – Lin Chiao Casting Co., Ltd.

- Lin Chiao Investment Casting Video and Picture

- Lin Chiao's Investment Casting in 2016

- Contact A Lost Wax Casting Supplier Now!

- Lin Chiao Casting Co., Ltd. Privacy Policy